-

Tile Making Machine

This machines can be equipped with an automatic elevator/skip for loading mix into hopper, agitator, an automatic pallet feeder, pallet ejector, brush for cleaning blocks and a run off conveyor (see above). It is suggested that you use a high capacity mixer of over 500 liters. A work force of 5 to 7 employees would keep this factory running at full capacity.

-

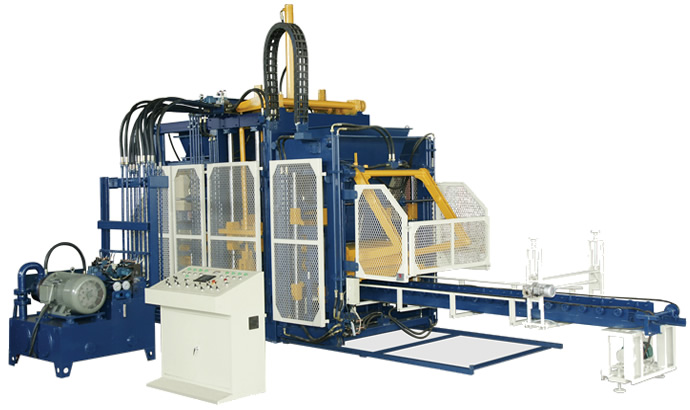

QT12-15 Block Making Machine

The block manufacturer can also realize substantial savings by using less cement. A ratio from 8:1 to 11:1 sand/cement can be achieved. This machine is designed for the powerful manufacturer with a steady year turnover and with a certain number casher to make the factory running, normally it is for a big project.

-

QT10-15 Block Making Machine

“QT” in QT 10-15 is given by Chinese government that all of the Concrete Block machine must use this Series Number.

“10” in QT10-15 stands for the production quantity is 10 blocks "390×190×190mm" per mould,

“15” in QT10-15 stands for one cycle time is 15 seconds.Since the moulds are changeable, the concrete equipment is able to produce different types of blocks/bricks, and this is a hydraulic machine can produces a stronger block, due to the greater pound pressure applied by the hydraulic system.

-

QT8-15 Block Making Machine

Since the moulds are changeable, the concrete equipment is able to produce different types of blocks/bricks, and this is a hydraulic machine can produces a stronger block, due to the greater pound pressure applied by the hydraulic system.

The block manufacturer can also realize substantial savings by using less cement. A ratio from 8:1 to 11:1 sand/cement can be achieved. This machine is designed for the manufacturer with a steady year turnover and with a certain number casher to make the factory running. -

QT6-15 Block Making Machine

The block manufacturer can also realize substantial savings by using less cement. A ratio from 8:1 to 11:1 sand/cement can be achieved. This machine is designed for the manufacturer with limited space, limited budget and the desire to achieve good quality, high volume of blocks, with the minimum cash outlay.

-

QT4-15 Block Making Machine

Since the moulds are changeable, the concrete equipment is able to produce different types of blocks/bricks, and this is a hydraulic machine can produces a stronger block, due to the greater pound pressure applied by the hydraulic system.00×4050×7600mm

Transportation: Double Axle Chassis

PRODUCT TYPE LIST

NEWS

Contact Us

Address:Industrial Equipment Zone,Zhengshang Road Zhengzhou Henan

Zip: 450000 China

Fax:+86-371-63935058

E-mail:sales@unique-cons.com

TEL:+86-371-63699132